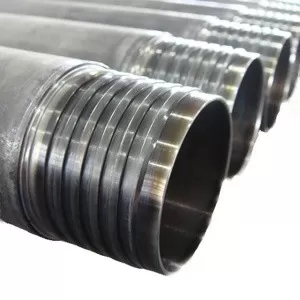

1.5m/ 3m ATW, BTW, NTW, HTW Wireline Drill Rod Heat Treatment Drill Pipes

1.5m/ 3m ATW, BTW, NTW, HTW Wireline Drill Rod Heat Treatment Drill Pipes

Introduction:

Rod handlers improve safety by keeping helpers away from energized components and potential injury from wrenches under power. Coring rod threads will jam in 20-30% of joint make-ups, meaning that time is lost, and 5% of the time the helper is back near the rotation unit, reducing safety. These jams add significant unproductive time either to unjam threads or rotate threads backward 100% of the time when manually making joints.

Our wireline rods feature a unique thread entry, nearly eliminating jams, upgrading safety for hands-free rod handling, where making and breaking of rods is mechanized. The threads also feature a coarser pitch with less rotation, making them faster to make up by hand, generating less fatigue, lower stress on the wrist and less potential for repetitive use injuries.

| Basic information | |

| Size: | ATW, BTW, NTW, HTW |

| Application: | Mineral Exploration Wireline Core Drilling Tools |

| Standard: | DCDMA |

| High Light: | machining drill rod |

| tool steel drill rod | |

| Length: | 1.5 Meter, 3 Meter, Or As Per Request |

| Process: | Heated Treatment |

| Material: | High Quality Steel |

Size Available as followings:

"Q" series: AQ, BQ, NQ, HQ, PQ,

“TW” series: ATW, BTW, NTW, HTW

Casing: AW, BW, NW, HW, HWT, PW

Wireline drill rod technical specifications:

| Size | O.D.(mm) | I.D.(mm) | Weight/3m(kg) | Weight/1.5m(kg) |

| A | 43.1 | 36.1 | 11 | 5.5 |

| B | 55.58 | 45.97 | 19.05 | 9.53 |

| N | 69.85 | 60.45 | 23.77 | 11.89 |

| H | 88.9 | 77.72 | 34.88 | 17.44 |

| P | 114.3 | 101.6 | 53.07 | 26.54 |

| ATW | 44.5 | 36.8 | 11.5 | 5.75 |

| BTW | 56.64 | 48.51 | 15.65 | 7.83 |

| NTW | 73.15 | 64.26 | 22.91 | 11.46 |

| HTW | 90.93 | 81.53 | 30.75 | 15.38 |