Spiral type integral blade tungsten carbide inserts stabilizer for hole size 3-7/8" with: Blade Lenth: 18 inches, Quantity of Blades: 03 Nos., Mid body Length: 1.50 meters,

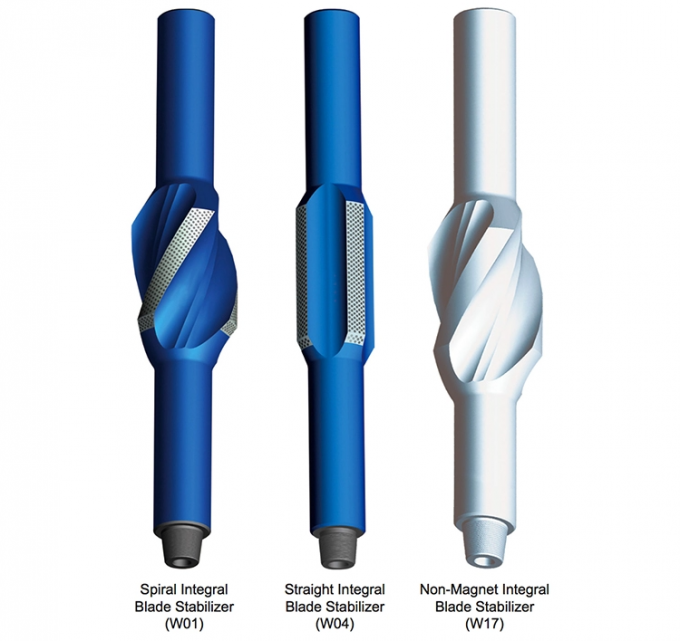

Spiral type integral blade tungsten carbide inserts stabilizer for hole size 3-7/8" with: Blade Lenth: 18 inches, Quantity of Blades: 03 Nos., Mid body Length: 1.50 meters, Mid Body Wall thickness:9.19mm,Mid body Outer Dia:2-7/8 inches, Joint Type (Pin&Box):2-3/8” MAYHEW JUNIOR, No. of flats for breakout wrench:02 Nos. on both ends

Spiral type integral blade tungsten carbide inserts stabilizer for hole size 3-7/8" with: Blade Lenth: 18 inches, Quantity of Blades: 03 Nos., Mid body Length: 1.50 meters, Mid Body Wall thickness:9.19mm,Mid body Outer Dia:2-7/8 inches, Joint Type (Pin&Box):2-3/8” MAYHEW JUNIOR, No. of flats for breakout wrench:02 Nos. on both ends

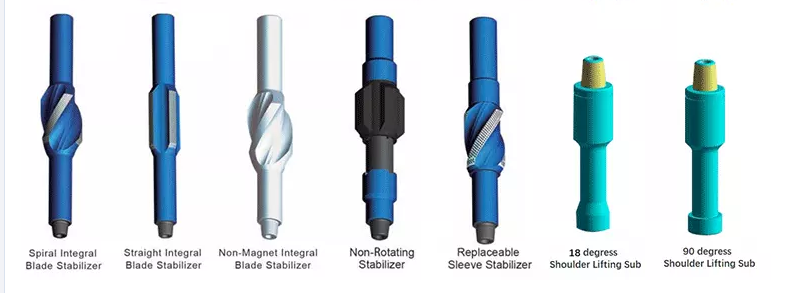

Roschen provides integral straight blade stabilizer, integral spiral blade stabilizer, replaceable sleeve stabilizer, non-rotating stabilizer (rubber sleeve stabilizer), hard facing stabilizer,3-Piece sleeve replaceable stabilizer, float valve stabilizer, spherical stabilizer, variable diameter stabilizer, etc. All above products comply with API Spec 7.

Integral 3-spiral blade stabilizer, integral 4-spiral blade stabilizer (string type, near bit type). The working hardfacing surface (also called as wall contact) materials available separately are carbide insert, insert diamond compound, low temperature brazing tungsten carbide slug,surface bead welding abrasive welding rod,etc.

| Spiral type integral blade tungsten carbide inserts stabilizer | ||||||||

| Technical Specifications and Parameters | ||||||||

| (in) | (mm) | End OD | ID | Kit Length (mm) | Connection | |||

| (mm) | (mm) | String type | Near bit type | |||||

| Top | Down | Top | Down | |||||

| 6 | 152.4 | 121 | 51 | 1200 | NC38 | 3 1/2 REG | ||

| 6 1/4 | 158.7 | |||||||

| 6 1/2 | 165.1 | |||||||

| 7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | 4 1/2 REG | ||

| 7 7/8 | 200 | |||||||

| 8 3/8 | 212.7 | 159 165 | 71 | 1600 1800 | NC46 NC50 | |||

| 8 1/2 | 215.2 | 159 | ||||||

| 165 | ||||||||

| 8 3/4 | 222.2 | 178 | ||||||

| 9 1/2 | 241.3 | 178 197 | 1600 | NC50 | NC50 | NC50 | ||

| 9 5/8 | 244.5 | 1800 | 6 5/8 REG | |||||

| 9 7/8 | 250.8 | |||||||

| 12 1/4 | 311.2 | 203 209 | 76 | 1800 | NC56 6 5/8 REG | NC56 6 5/8 REG | NC56 6 5/8 REG | 6 5/8 REG |

| 16 | 406 | 229 241.3 | 2000 2200 | NC61 7 5/8 REG | NC61 7 5/8 REG | NC61 7 5/8 REG | NC61 7 5/8 REG | |

| 17 1/2 | 444.5 | |||||||

| 24 | 609.6 | |||||||

| 26 | 660.4 | |||||||

| 28 | 711.2 | |||||||