Boart Longyear wireline core barrel NQTK core barrel for exploration core drilling

Boart Longyear wireline core barrel NQTK core barrel for exploration core drilling

Boart Longyear wireline core barrel NQTK core barrel for exploration core drilling

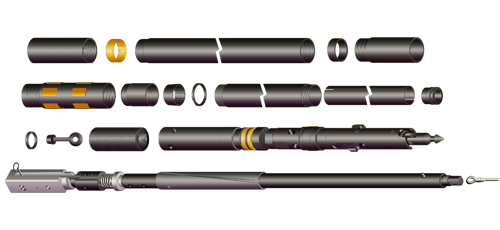

Roschen Boart Longyear Q/QTK wireline systems (represented to the left) consist of the core barrel assembly and the overshot assembly. Both assemblies are integral to the wireline system.

The core barrel assembly is composed of the inner-tube group and outer-tube group. The inner-tube group is composed of: - Head Assembly - Inner Tube - Core Lifter Case - Core Lifter - Stop Ring The inner-tube group collects the core sample during the drilling process and is independent of the outer-tube group. The outer-tube group is composed of the remainder of the core barrel components: - Locking Coupling - Adapter Coupling - Outer Tube The outer-tube group always remains at the bottom of the hole and houses the inner-tube group during the drilling process. Q3 wireline systems (represented to the right) consist of the same groups as the Q and QTK but utilize a third tube called an inner-tube liner or split tube. The liner is placed inside the inner tube.

Applications

Roschen Boart Longyear Q systems are ideal for use in most drilling conditions and are available for application in standard DCDMA hole sizes (A, B, N, H, P).

Roschen Boart Longyear QTK systems are optimized to allow for a larger core sample while retaining the same hole, low fluid pressure, and robust inner and outer tubes. QTK systems are offered in the A, B and N sizes.

Boart Longyear Q3 systems enable integral core recovery when drilling coal, clay bearing or highly fractured formations. The liner, or split tube, retains the core sample in its received state for easier loading into sample trays or for storage and subsequent presentation to the geologist. The Q3 system is only available in surface configurations and is available in N, H and P sizes.

The High Productivity Coring System is a time saving surface coring system which includes the Quick Descent head assembly, V-Wall coring rod and the Stage3 diamond coring bit.

| SIZE | CORE Ø | HOLE Ø |

| AQTK | 35.5 mm (1-3/8 in) | 48 mm (1-7/8 in) |

| BQ | 36.4 mm (1-7/16 in) | 60 mm (2-3/8 in) |

| BQTK | 40.7 mm (1-5/8 in) | 60 mm (2-3/8 in) |

| NQ | 47.6 mm (1-7/8 in) | 75.7 mm (3 in) |

| NQTK (NQ2") | 50.6 mm (2 in) | 75.7 mm (3 in) |

| NQ3 | 45 mm (1-3/8 in) | 75.7 mm (3 in) |

| HQ | 63.5 mm (2-1/2 in) | 96 mm (3-3/8 in) |

| HQ3 | 61.1 mm (2-3/8 in) | 96 mm (3-3/8 in) |

| PQ | 85 mm (3-3/8 in) | 122.6 mm (4-7/8 in) |

| PQ3 | 83 mm (3-1/4 in) | 122.6 mm (4-7/8 in) |