Roller Reamer

Roller Reamer with interchangeable roller cone tools for soft formation to hard formation reaming drilling

Roller Reamer

Model 3RXC and 6RXC mud-lubricated roller reamers are at the core of ROSCHEN Oilfield Manufacturing “Hole Gauge” Assurance drilling tools. They offer easy rig floor replacement of cutters and parts that are also interchangeable with most other brands.

No welding is necessary to replace the blocks and only when needed, special repair tools are supplied for safety.

ROSCHEN ROLLER REAMER FEATURES:

Three roller cutter types are offered for formation-matched reamer performance.

● The type “VHM” soft formation cutters deliver maximum reaming action in soft formations like soft lime and shale. Service life of cutters is enhanced with hardened and carburized teeth.

● The type “QHM” medium to hard formation cutters are most suitable for cherty formations to hard formations such as dolomite, hard lime and chert.

● Knobby “KHM” cutters are prescribed for very hard formations. Knobby cutters deliver reliable reaming performance in hard, abrasive and semi-abrasive formations such as granite and sand.

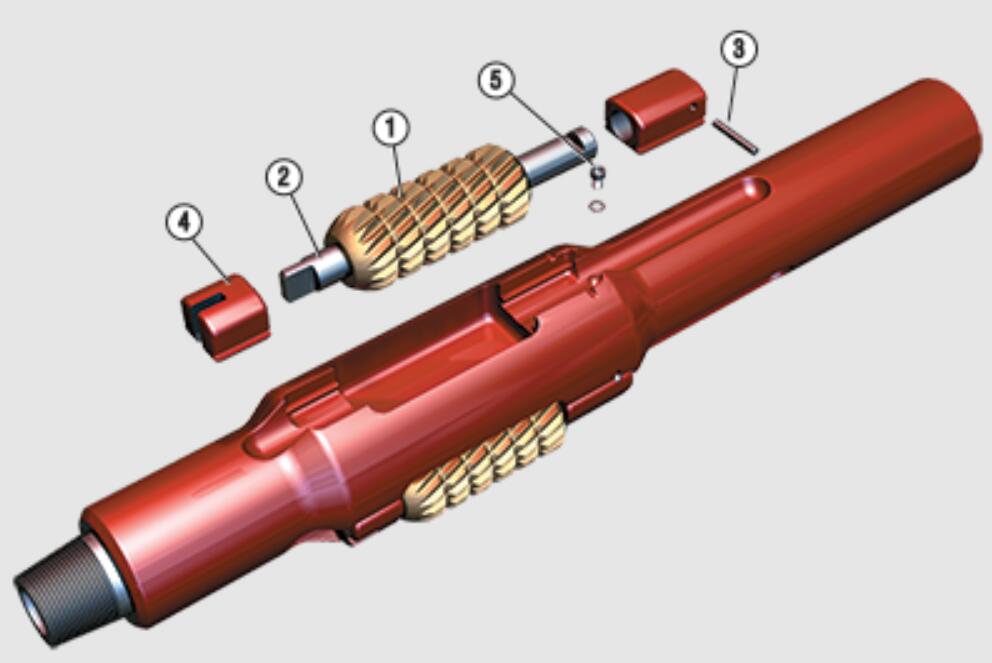

ROSCHEN ROLLER REAMER COMPONENTS

1. Cutters – See ROSCHEN Roller Reamer Features

2. Reamer Pin – A large diameter pin, carburized and hardened, ensures good bearing wear characteristics. The reamer pin is prevented from rotating by the engagement of the end of the pin with slot in the body bearing block.

3. Cross Pin – This drive-fit cross-pin arrangement safely retains the main reamer pin and reamer cutter while providing a simple, yet safe, locking device.

4. Drive-Fit Body Bearing Blocks – Blocks properly position the cutter in the body to cut a full-gauge hole. Blocks are readily changeable by the drilling crew.

5. Socket Head Cap Screws and Lock Washers – Included as secondary locking device for the reamer pins on each body for hole sizes 6 inches and larger.

CAUTION: Surfaces of block are carburized. Beware of fragments of this brittle surface breaking off under impact of sledgehammer. WEAR SAFETY GLASSES AT ALL TIMES

ROSCHEN ROLLER REAMER APPLICATION:

Near-Bit Configuration:

The ROSCHEN 3RXC roller reamer is a three-point reamer that can be run between bit and drill collar to eliminate unnecessary back-to-bottom reaming with a new bit.

Drill String Configuration:

In this configuration the ROSCHEN 3RXC is run between drill collars to ream out doglegs, key seats, and ledges in the hole. This reamer arrangement offers the most mitigation for prevention of hole gauge impairment that can result in a stuck-pipe.

Six Point (6RXC) Reamer Configuration:

The 6RXC roller reamer is run between the drill collars and the bit to afford greater stabilization and reaming capacity. It is very effective in preventing sharp hole angle changes when run as a packed hole assembly.