Reverse Circulation Drill Bits

Reverse Circulation Drill Bits

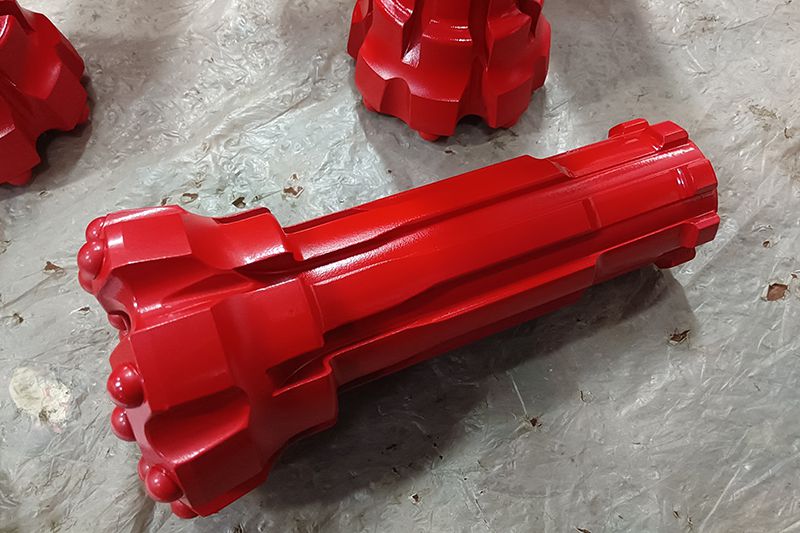

The reverse circulation drill bits are engineered to perfection, meeting market demands through extensive self-testing and customer feedback. Our commitment to precision machining, combined with advanced heat treatment techniques and the use of high-quality YK05 carbide, ensures enhanced quality and performance for the drill bits.

Experience Excellence in Drilling with Our Reverse Circulation Drill Bits

The reverse circulation drill bits are engineered to perfection, meeting market demands through extensive self-testing and customer feedback. Our commitment to precision machining, combined with advanced heat treatment techniques and the use of high-quality YK05 carbide, ensures enhanced quality and performance for the drill bits.

With stable inventory quantities for standard-sized drill bits, ROSCHEN ensures quick delivery, meeting customer expectations promptly. Additionally, we offer customized services, guaranteeing quality and quantity within the specified time frame. Notably, the reverse circulation drill bits are interchangeable with international brands that share the same tail design, highlighting the universality and quality assurance of our products.

| RC Bit Specifications | |||

| Model | Shank | Bit diameter (mm) | Outside diameter (mm) |

| RE531 | RE531 | 84-100 | 82-98 |

| RE004 | RE004 | 111-127 | 109-125 |

| RE542 | RE542 | 113-130 | 111-128 |

| RE543 | RE543 | 120-135 | 118-133 |

| RE545 | RE545 | 122-140 | 120-138 |

| RC40 | PR40 | 124-142 | 122-140 |

| RC52 | PR52 | 126-146 | 124-144 |

| PR52R | PR52R | 126-146 | 124-144 |

| PR54 | PR54 | 136-150 | 134-148 |

| RE547 | RE547 | 130-146 | 128-144 |

| MX5456 | MX5456 | 136-152 | 134-150 |

Features

. The unique design and strict tolerance control ensure precise and reliable tail connections, crucial for successful sampling operations.

. Professional heat treatment techniques enhance the wear resistance and durability of our drill bits, ensuring efficient and stable drilling operations.

3. The application of CNC precision machining technology results in clean and smooth tail slots, preventing debris accumulation and ensuring smooth drilling processes and accurate sampling.

. The drill bits not only offer high sampling efficiency but also boast low noise and environmental friendliness, aligning with eco-friendly requirements and providing a more comfortable drilling environment.

. Simplified operation methods of the drill bits improve drilling efficiency while guaranteeing sampling accuracy, making on-site operations more convenient and efficient.

ROSCHEN, a specialist manufacturer of rock drilling tools, has made a firm commitment to fulfill customers' expectations by providing premium quality drill rods, drill bits and other drilling accessories.

At ROSCHEN, our primary goal is to get customers' drilling tasks done efficiently and effectively. Our experts of rock drill tools demonstrate their expertise in a number of different projects of aggregate mining, water well drilling, tunnel boring and piling. Trusted by global drilling contractors and customers who looking for high quality drilling tools for their drilling rigs and rock drilling machines, we would be honored to have the opportunity to earn your trust and provide you with rock drilling products that meet your application needs.