Casing Shoe NW HW PWT

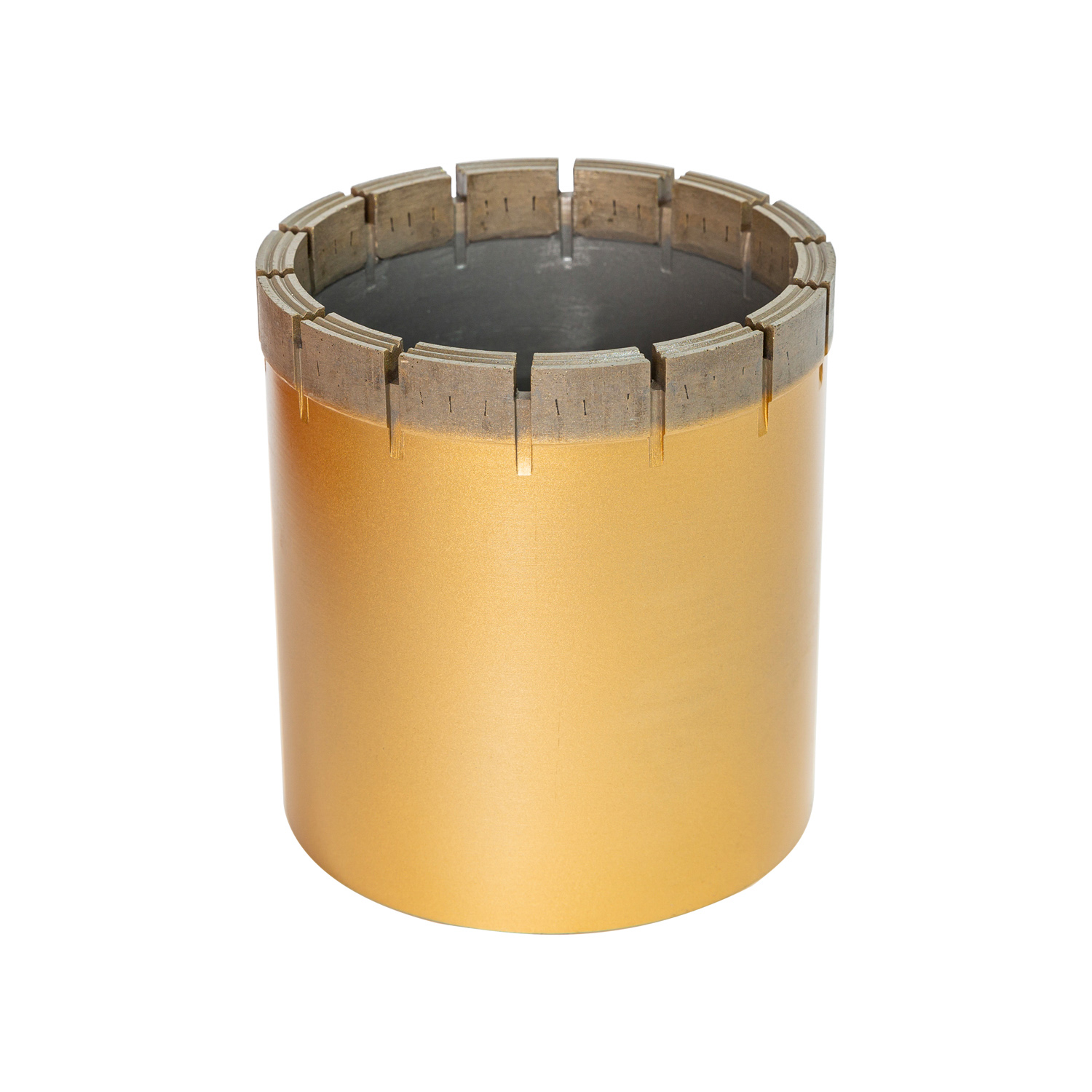

Casing Shoe

The casing shoe bit is mainly used in handling casing tube in the shallow earth surfaces, and we have casing shoes bit in diferent hardness to better fit various

casing tube bits

The casing shoe diamond bit is mainly made up of diamond single crystal steel body, tungsten carbide and polycrystalline diamond

Main functions of casing shoe:

1): protect casing ends from distortion.

2): help casing pass through stratum to bed rock.

3): carry mud to earth surface.

4): help down-pass of casing when drill rod is in hole .

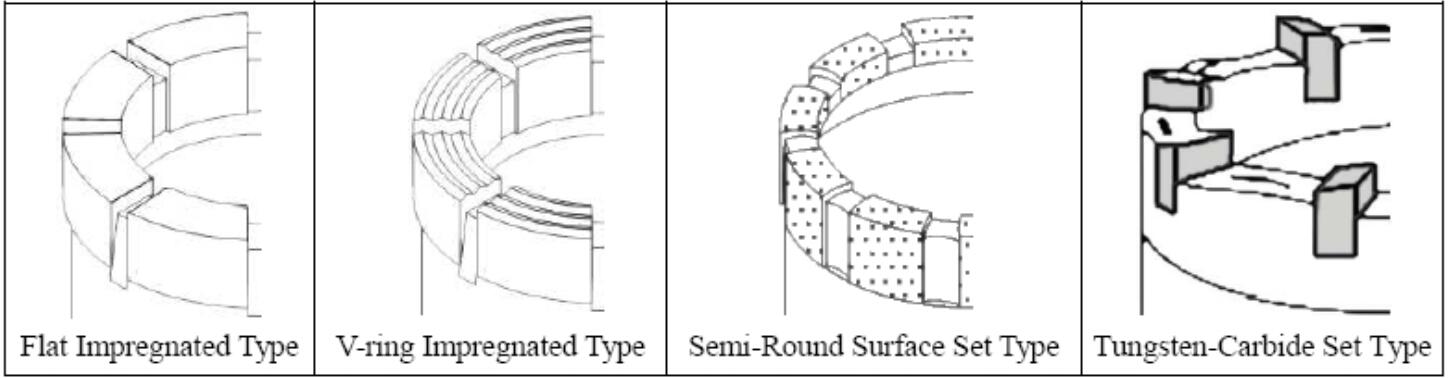

Impregnated diamond casing shoe is the most commonly used as it has the widest range of application and is generally the most eficient tool for advancing casing through overburden layers. We have two crown types of impregnated diamond casing shoes avilable, fat and V-ring.

Impregnated diamond casing shoe is the most commonly used as it has the widest range of application and is generally the most efficient tool for advancing casing through overburden layers. We have two crown types of impregnated diamond casing shoes available, flat and V-ring.

Surface set diamond casing shoe differs from the impregnated type in that they are set with a single layer of natural drill diamond in a pre -determined pattern on the working surfaces of the tool. Surface set diamond casing shoes are recommended for use when drilling relatively soft and abrasive formations such as sandstone or limestone.

Tungsten-Carbide casing shoe set with large tungsten-carbide elements that are physically embedded into the crown of the tool. Tungsten-carbide does not possess the hardness of diamond but it is very cost effective means of drilling through softer unconsolidated formations. The application of this type of casing shoe is primarily in geotechnical soil investigation or for advancing casing tubes through overburden layers that are composed mainly of clay, sand, gypsum or soft shale.

| Casing Bit Specifications | |||||

| Type | Size | Outside Diameter | Inside Diameter | ||

| inch | mm | inch | mm | ||

| Standard Casing Shoes | RW | 1.475 ~ 1.465 | 37.46 ~ 37.21 | 1.188 ~ 1.183 | 30.18 ~ 30.05 |

| EW | 1.1880 ~ 1.870 | 47.75 ~ 47.50 | 1.497 ~ 1.492 | 38.02 ~ 37.90 | |

| AW | 2.350 ~ 2.340 | 59.69 ~ 59.44 | 1.902 ~ 1.897 | 48.31 ~ 48.18 | |

| BW | 2.970 ~ 2.960 | 75.44 ~ 75.19 | 2.377 ~ 2.367 | 60.38 ~ 60.12 | |

| NW | 3.620 ~ 3.610 | 91.95 ~ 91.70 | 2.997 ~ 2.987 | 76.12 ~ 75.87 | |

| HW-CDDA | 4.632 ~ 4.617 | 117.65 ~ 117.27 | 3.930 ~ 3.920 | 99.82 ~ 99.57 | |

| HW-DCDDA | 4.632 ~ 4.617 | 117.65 ~ 117.27 | 3.980 ~ 3.970 | 101.09 ~ 100.84 | |

| HWT | 4.632 ~ 4.617 | 117.65 ~ 117.27 | 3.930 ~ 3.920 | 99.82 ~ 99.57 | |

| PW | 5.660 ~ 5.640 | 143.76 ~ 143.26 | 4.865 ~ 4.850 | 123.57 ~ 123.19 | |

| PWT | 5.660 ~ 5.640 | 143.76 ~ 143.26 | 4.865 ~ 4.850 | 123.57 ~ 123.19 | |

| SW | 6.800 ~ 6.780 | 172.72 ~ 172.21 | 5.948 ~ 5.933 | 151.08 ~ 150.70 | |

| UW | 7.815 ~ 7.785 | 198.50 ~ 197.74 | 6.916 ~ 6.896 | 175.67 ~ 175.16 | |

| ZW | 8.825 ~ 8.795 | 224.15 ~ 223.40 | 7.987 ~ 7.967 | 202.87 ~ 202.36 | |

| Metric Casing Shoes | 46 mm | 1.818 ~ 1.808 | 46.18 ~ 45.92 | 1.462 ~ 1.452 | 37.13 ~ 36.88 |

| 56 mm | 2.210 ~ 2.200 | 56.13 ~ 55.88 | 1.855 ~ 1.845 | 47.12 ~ 46.87 | |

| 66 mm | 2.603 ~ 2.593 | 66.12 ~ 65.87 | 2.249 ~ 2.239 | 57.12 ~ 56.87 | |

| 76 mm | 2.997 ~ 2.987 | 76.12 ~ 75.87 | 2.643 ~ 2.633 | 67.13 ~ 66.88 | |

| 86 mm | 3.391 ~ 3.381 | 86.13 ~ 85.88 | 3.037 ~ 3.027 | 75.14 ~ 76.89 | |

| 101 mm | 3.985 ~ 3.970 | 101.22 ~ 100.84 | 3.460 ~ 3.445 | 87.88 ~ 87.50 | |

| 116 mm | 4.575 ~ 4.560 | 116.20 ~ 115.82 | 4.063 ~ 4.048 | 103.20 ~ 102.82 | |

| 131 mm | 5.165 ~ 5.150 | 131.19 ~ 130.81 | 4.700 ~ 4.685 | 119.38 ~ 119.00 | |

| 146 mm | 5.755 ~ 5.740 | 146.18 ~ 145.80 | 5.244 ~ 5.229 | 133.20 ~ 131.81 | |

| Standard Casing Shoes (For use with DCDMA and CDDA Standard Casing) | BW | 2.970 ~ 2.960 | 75.44 ~ 75.19 | 2.220 ~ 2.210 | 56.39 ~ 56.13 |

| NW | 3.620 ~ 3.610 | 91.95 ~ 91.70 | 2.845 ~ 2.835 | 72.26 ~ 72.00 | |

| HW | 4.632 ~ 4.617 | 117.65 ~ 117.27 | 3.782 ~ 3.772 | 96.06 ~ 95.81 | |

| Wide-Kert Casing Bits (For use with DCDMA and CDDA Standard Casing) | BW (BWL) | 2.970 ~ 2.960 | 75.44 ~ 75.19 | 1.880 ~ 1.870 | 47.75 ~ 47.50 |

| NW (NWL) | 3.770 ~ 3.755 | 95.76 ~ 95.38 | 2.505 ~ 2.495 | 63.63 ~ 63.38 | |

| HW (HWL) | 4.815 ~ 4.795 | 122.30 ~ 121.80 | 3.350 ~ 3.340 | 85.09 ~ 84.84 | |

| British Standard BS879 Water Well Casing Shoes |

4 inch | 4.635 ~ 4.615 | 117.73 ~ 117.22 | 3.824 ~ 3.809 | 97.13 ~ 96.75 |

| 5 inch | 5.660 ~ 5.640 | 143.76 ~ 143.26 | 4.833 ~ 4.813 | 122.75 ~ 122.25 | |

| 6 inch | 6.800 ~ 6.780 | 172.72 ~ 172.21 | 5.833 ~ 5.818 | 148.15 ~ 147.75 | |

| 8 inch | 8.835 ~ 8.815 | 224.41 ~ 223.90 | 7.835 ~ 7.815 | 199.01 ~ 198.50 | |

| 10 inch | 10.940 ~ 10.920 | 277.88 ~ 277.37 | 9.825 ~ 9.805 | 249.56 ~ 249.05 | |

| Note: The above size is only for reference and non standard set diameters and maybe available on request. | |||||

Best regards,

Phiger Leo

Direct Line: 0086-137-6419 5009

WeChat/WhatsApp:: +86-137-6419 5009

================================================================

ROSCHEN@ INC.

ROSCHEN@ GROUP LIMITED

ROBERT ROSCHEN@ LIMITED

ROSCHEN@ HOLDINGS LIMITED

HEFEI ROSCHEN@ TOOL CO., LTD.

ROSCHEN@ GEOLOGICAL TOOL CO.,LTD.

SHANGHAI ROSCHEN@ INTERNATIONAL CO., LTD.

ROSCHEN@ GEOLOGICAL INSTRUMENTS CO., LTD.

EMAIL: roschen@roschen.com ; roschen@roschen.net

Website: http://www.roschendrill.com

http://www.roschenmining.com

http://www.roschendrilling.com

http://www.explorationcoredrilling.com

http://www.roschen.net

http://www.roschen.cn

http://www.roschen.com

https://www.drillpipefactory.com

================================================================