Atlas Copco Overburden Drilling Tools

Atlas Copco Overburden Drilling Tools

Atlas Copco overburden drilling products at Rock Drill Sales and Service.

As much as 90% of the land surface of the earth is covered with loose, unconsolidated material such as soil, clay, silt, sand, gravel and boulders, which varies in depth from a few centimetres to hundreds of meters.

Drilling through this so-called overburden is often problematic, due to the tendency of the earth to cave in behind the drill bit.

This makes it difficult to retrieve the drill string after the hole has been drilled. In practice, the bore hole is often lost before a casing tube can be inserted to support it.

Other problems are caused by cavities or porous ground, which interfere with the circulation of the flushing medium and prevent the drill cuttings from being flushed out of the hole.

In places where overburden strata are mixed, or when their drillability is unknown, it is difficult for the driller to decide what tools to use in order to get the best overall results

without risking the loss of equipment in the hole.

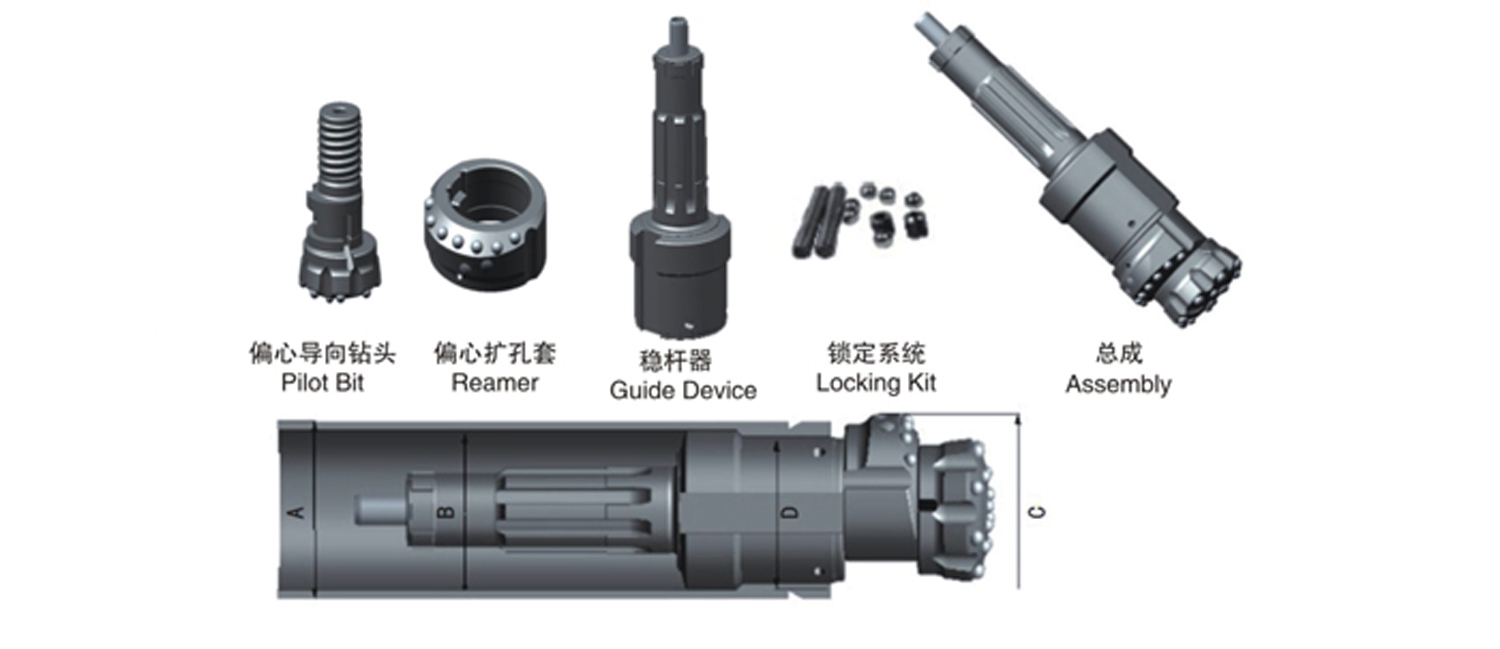

The best solution for dealing with such problems is to use ODEX equipment.

| Out Dia. (A) mm | Inner Dia. (B) mm | Reamed Dia. (C) mm | Inner Dia.of Casing Shoe (D) mm | Hammer Type (E) | Drill Pipe mm |

| 108 | 93 - 99 | 118 | 87 | ROS35/QL30 | 76 |

| 114 | 102 - 108 | 123 | 93 | ROS35/QL30 | 76 |

| 127 | 115 - 117 | 136 | 102 | ROS35/QL30 | 76 |

| 140 | 124 - 128 | 152 | 115 | ROS45/QL40 | 76 |

| 146 | 130 - 134 | 154 | 121 | ROS45/QL40 | 76 |

| 168 | 148 - 156 | 185 | 140 | ROS55/QL50 | 89 |

| 178 | 158 - 166 | 195 | 150 | ROS55/QL50 | 89 |

| 194 | 174 - 182 | 211 | 166 | ROS65/QL60 | 114 |

| 219 | 199 - 207 | 237 | 193 | ROS65/QL60 | 114 |

| 245 | 225 - 233 | 260 | 210 | ROS85/QL80 | 114 |

| 273 | 253 - 257 | 308 | 241 | ROS85/QL80 | 114 |

| 325 | 305 - 309 | 378 | 281 | SD10/NUMA100 | 127 |

| Order Guide: Outer Dia.(A)+Inner Dia.(B)+Reamed Dia.(C)+Inner Dia.of Casing Shoe(D)+Hammer Type(E) | |||||