Heavy Weight Drill Pipe

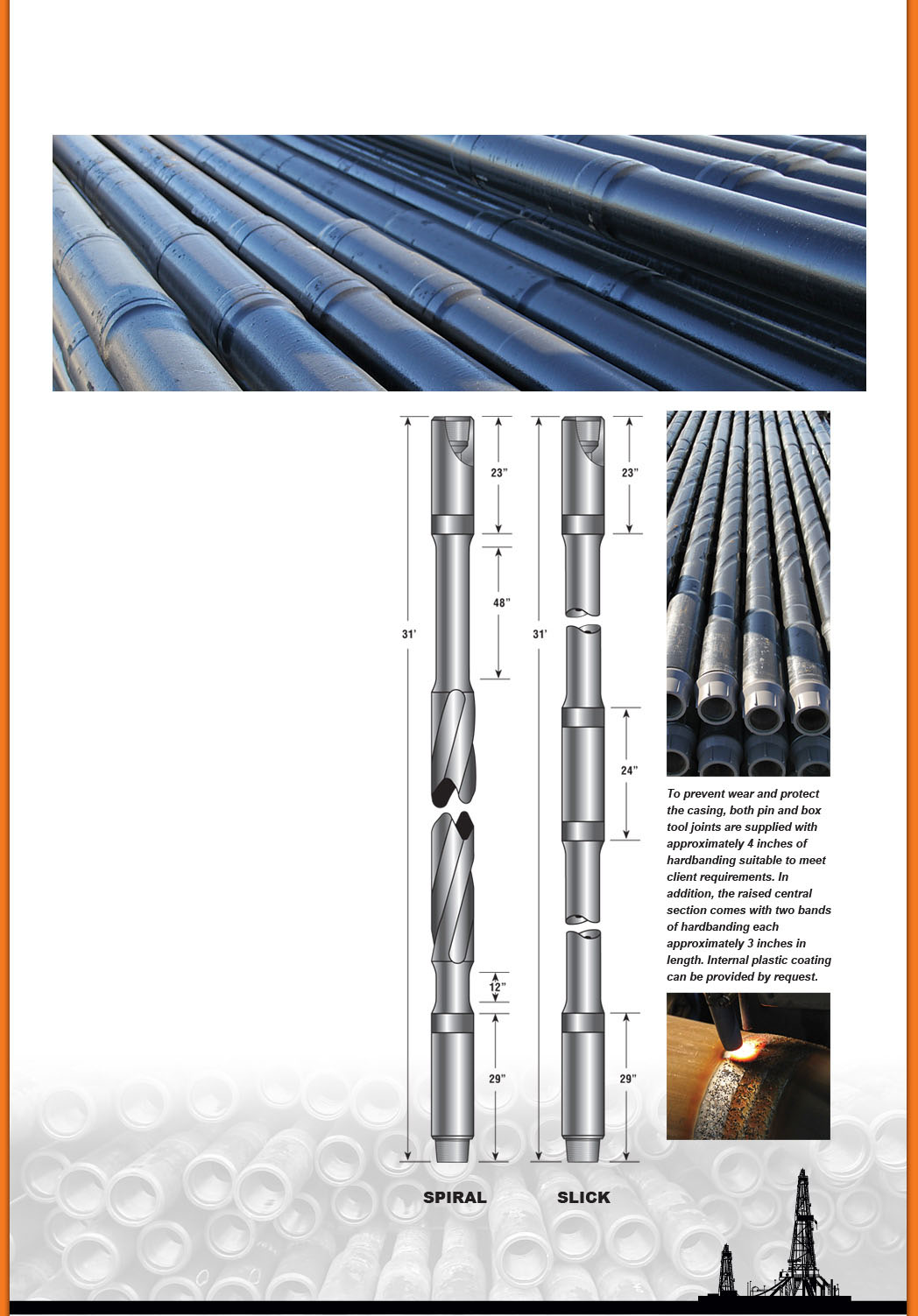

Roschen manufactures heavy weight drillpipe (HWDP) in a complete range of sizes from 3 1/2" to 6 5/8". HWDP consists of a heavy wall tube with a raised central section. Extra-length tool joints are friction welded on to the specially machined thick wall tube. The tube is AISI 1340 or equivalent material and the tool joints are AISI 4145-H modified steel. In addition, to extend fatigue life of the pipe, threads are cold-rolled and TSC HDD recommends that pin ends have relief grooves and boxes have bore-backs. Connections are phosphate coated to reduce galling and control corrosion. All HWDP is manufactured in accordance with API 7.1 Specification.

Heavy weight drill pipe (HWDP) is included in the drill string to offer a gradual transition between the heavy, stiff drill collars and the flexible drill pipe. This helps prevent excessive stress concentrations in the drill pipe by improving the Bending Stress Ratios (BSR) to acceptable industry standards. Without HWDP, the drill pipe would be at significant risk to fatigue.

Because HWDP is more flexible, it helps increase directional control while reducing potential fatigue problems that often occur in horizontal and high-angle drilling. HWDP is most commonly used in directional drilling where it also helps to control torque, reduce buckling and prevent differential sticking. Heavy weight drill pipe placed between the drill collars and the drill pipe significantly reduces operational risks related to fatigue in this stress-prone area.