Standard Penetration Test Equipment SPT Automatic Travel Hammer 2" 63.5kg

Standard Penetration Test

Standard Penetration Test

The standard penetration test (SPT) is an in-situ dynamic penetration test designed to provide information on the geotechnical engineering properties of soil. This test is the most frequently used subsurface exploration drilling test performed worldwide. The test procedure is described in ISO 22476-3, ASTM D1586 and Australian Standards AS 1289.6.3.1. The test provides samples for identification purposes and provides a measure of penetration resistance which can be used for geotechnical design purposes. Many local and widely published international correlations which relate blow count, or N-value, to the engineering properties of soils are available for geotechnical engineering purposes.

Roschen is manufacturing Automatic SPT Hammer and Hydraulic SPT Hammer by using high quality raw material for Standard Penetration Test (SPT). Usage of Automatic SPT Hammer; SPT Drive Rods and a Split Tube Sampler are connected to base of the anvil of Automatic SPT Hammer and driven into the ground by the falling weight of 63.5 kg complete mechanism by automatically.

The standard requires that a certificate of calibration of the Er value be available and provides a recommended method for determining the energy ratio and reporting the results. This paper focuses on the measurement of the energy ratio, and the results and additional criteria that can be used to determine best practice and quality assurance for the SPT test.

Although this paper focuses on BS EN ISO 22476-3, it should be noted that the British Standard covering dynamic sampling, BS EN ISO 22476-2: 2005, was implemented at the same time and also requires energy ratios for that equipment to be determined.

In late 2008 an instrument to measure energy ratio that fully complies with the requirements in the British Standards became available in the UK, enabling energy ratio tests to be carried out on SPT

hammers, automatic hammers and dynamic sampling drop weights.

Whilst these tests are conducted, additional measurements are made of drop height, drop weight and observations of the condition of each test hammer and test equipment.

Results of these observations are maintained in The Drilling Academy database, which has been used in this paper to examine energy ratio measurements, their implications and other variables that can influence energy loss and variations in energy ratio.

The majority of design calculations have previously used N values direct from the field, then compared these un-normalised results with similar, uncorrected, published results and correlations available in the technical literature.

As several different types of SPT test equipment are used to conduct the tests, their varying efficiencies influence the N value. Researchers and practitioners therefore recommend that the measured

energy transferred to the rod should be normalised to 60% of the theoretical potential energy, N60.

Roschen design procedures now require partial factors of safety to be used, which in turn requires better understanding and reliance of the original data.

The standard provides examples of possible methods for calculating normalised N values using correction factors. Although these formulae are only provided for tests within sands, the significant point is

the use of N60.

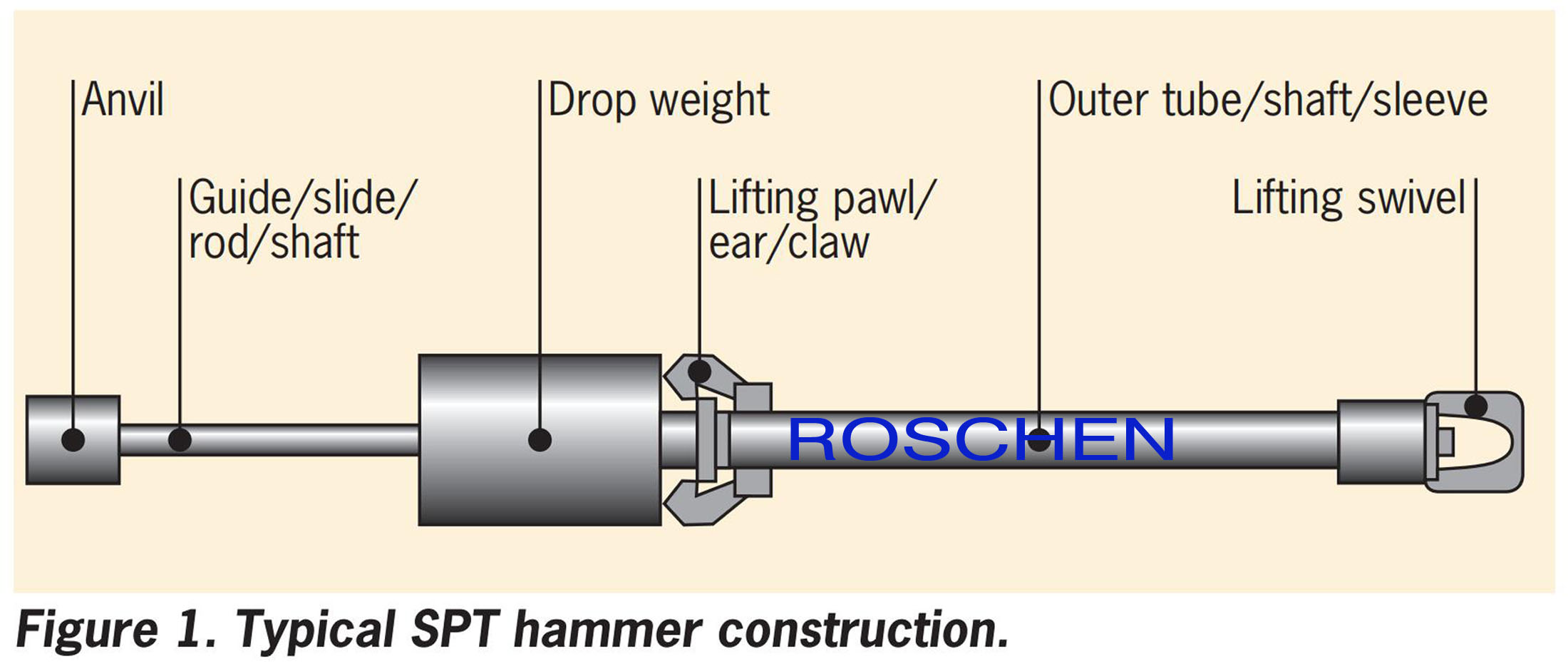

General construction of the SPT equipment

There is a significant range of types of hammer and their construction, as well as their method of operation.

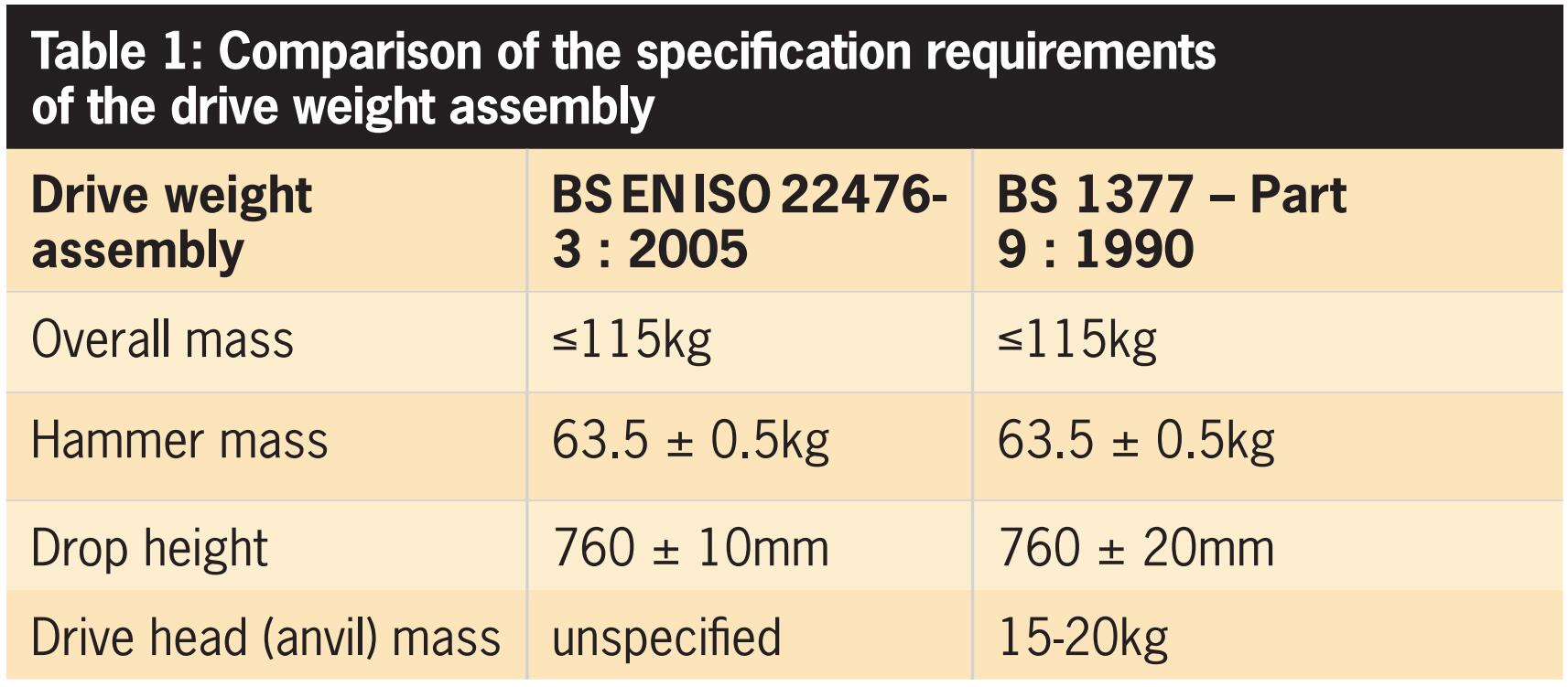

Early test methods described a standardised weight of 140lbs falling through 30ins, which subsequently became today’s standard weight of 63.5kg falling through 760mm.

Most hammers are manufactured to this standard specification, which in general complies with the requirements of the British Standard relevant at the time of manufacture.

Three types of SPT hammer were investigated in this study. The first, and most common of those studied, uses the winch rope on the rig and a two claw/pawl latching mechanism to lift the weight (Figure 1), although hammers with three claws have also been tested. The SPT hammer drop weight is automatically tripped when the pawls reach a raised section on the guide rod. The distance from the anvil to the raised section is the drop height (760mm ±10mm in the standard).

The second main type of SPT equipment comprises chain-driven drop weights. This is the standard mechanism used on dynamic sampling rigs, where the drop weight is lifted by a moving chain with an integral latch that allows the weight to be picked up. The weight is lifted up one or two guide rods, and when the weight reaches the top of its travel it is released from the latch. As the test is carried out the sliding carriage carrying the drop weight follows the weight down.

The third type is a new hammer, developed by Geotechnical Engineering, which is also chain driven, but after each blow the carriage is automatically lifted from the drop weight, ensuring that only the weight of the hammer performs the test. For the purposes of this paper this type of SPT hammer has been called an “automatic hammer”.

The construction and engineering of the rods, sleeve, claws etc can be completed using standard measurements. However, the construction of a pre-determined weight from a cylindrical steel mass is less straightforward. In most cases, as the material density is known and rarely changes, the weights are engineered using pre-determined dimensions (diameter and length).

Although the dimensions are checked while machining, it is not typical for weights to be physically weighed before the SPT hammer is assembled and despatched to the user, which would appear surprising given that the weight has been a prerequisite in both the old and new standards.

ROSCHEN@ INC.

ROSCHEN@ GROUP LIMITED

ROBERT ROSCHEN@ LIMITED

ROSCHEN@ HOLDINGS LIMITED

HEFEI ROSCHEN@ TOOL CO., LTD.

ROSCHEN@ GEOLOGICAL TOOL CO.,LTD.

SHANGHAI ROSCHEN@ INTERNATIONAL CO., LTD.

ROSCHEN@ GEOLOGICAL INSTRUMENTS CO., LTD.

EMAIL: roschen@roschen.com ; roschen@roschen.net

Website: http://www.roschendrill.com

http://www.roschenmining.com

http://www.roschendrilling.com

http://www.explorationcoredrilling.com

http://www.roschen.net

http://www.roschen.cn

http://www.roschen.com